As Beijing tightens its grip on critical minerals, America’s defense industry and tech sector face an unprecedented vulnerability threatening national security and economic stability

Breaking News: China has announced sweeping restrictions on rare earth exports effective December 1, 2025, threatening U.S. weapons manufacturing including F-35 fighter jets, Tomahawk missiles, and critical defense systems. Rare earth mining stocks have surged up to 200% as investors bet on a domestic production renaissance.

The Silent Weapon That Could Cripple American Defense

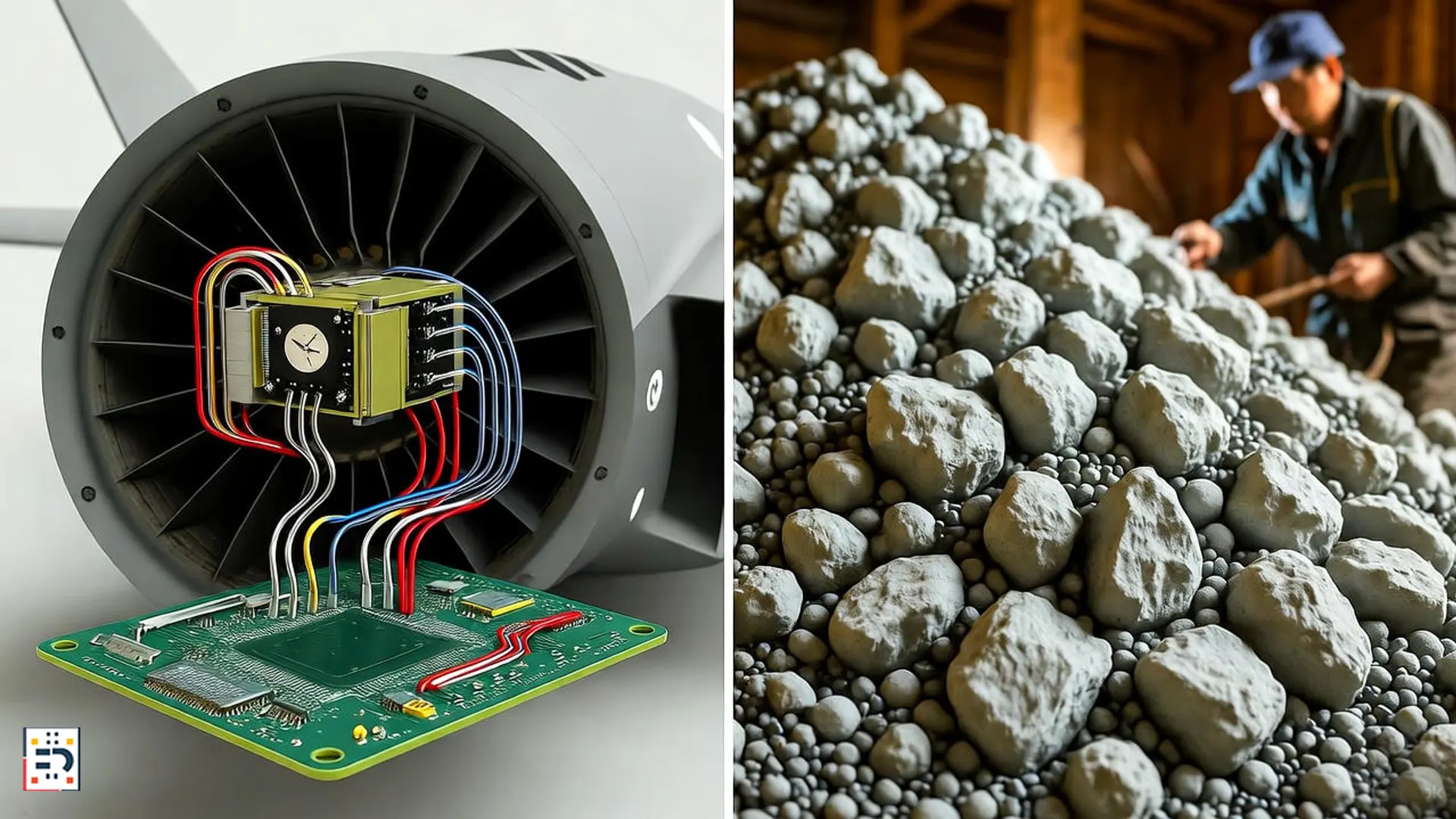

While headlines focus on tariffs and trade wars, a quieter but far more dangerous crisis is unfolding in the bowels of America’s supply chains. China has announced it will not allow the export of rare earth materials for use by foreign militaries, with rare earth magnets being crucial components in U.S. weapons such as the F-35 warplane, Tomahawk missiles and unmanned aerial vehicles. This isn’t just about trade leverage—it’s about national security at its most fundamental level.

The timing is no coincidence. The new restrictions, announced by China’s Ministry of Commerce in October 2025, come in advance of an expected meeting between United States President Donald Trump and his Chinese counterpart, Xi Jinping, later this month. Beijing is sending a clear message: it holds the keys to America’s military-industrial complex, and it’s not afraid to use them.

What Makes Rare Earth Elements So Critical?

Despite their name, rare earth elements aren’t actually rare in terms of geological abundance. What’s rare is the ability to mine, process, and refine them economically—and China has spent decades perfecting this art while the rest of the world watched.

Critical Stats: China controls almost 70% of rare earth extraction and 90% of rare earth processing globally. The U.S. was almost entirely dependent on foreign countries for rare earths in 2023, with China representing about 70% of imports.

Rare earths are crucial for various defense technologies, including:

- F-35 fighter jets and advanced military aircraft

- Virginia-class and Columbia-class submarines

- Tomahawk missiles and precision-guided munitions

- Radar systems and electronic warfare equipment

- Predator unmanned aerial vehicles (UAVs)

- Joint Direct Attack Munition (JDAM) smart bombs

Beyond defense, every smartphone vibration, wind turbine blade, and electric vehicle motor depends on these 17 elements with tongue-twisting names like neodymium, dysprosium, and praseodymium. The global race for rare earth materials has intensified dramatically in 2025.

The New Rules: A Game-Changing Escalation

China’s latest move represents a dramatic escalation in economic warfare. Under the new rules effective December 1, 2025, any magnet containing even trace amounts of Chinese-sourced rare earths—or made using Chinese methods—now requires Beijing’s explicit approval for export. Think about that for a moment: even if you source raw materials elsewhere, if you use Chinese processing technology, you’re still subject to Beijing’s control.

The five metals added to the restricted list are holmium, erbium, thulium, europium and ytterbium, in addition to seven minerals China placed export restrictions on earlier this year including samarium, gadolinium, terbium, dysprosium, lutetium, scandium and yttrium. Each of these elements plays a critical role in modern technology, from laser-guided missiles to MRI machines.

Critical Threshold: Foreign entities must now obtain a license from Beijing to export any products containing over 0.1% of domestically-sourced rare earths, or manufactured using China’s extraction, refining, magnet-making or recycling technology. That 0.1% threshold means virtually any product that touches Chinese rare earth supply chains requires Beijing’s permission to leave the country.

The Defense Industry’s December Deadline

Under the new rules, starting December 1, 2025, companies with any affiliation to foreign militaries—including those of the United States—will be largely denied export licenses. December 1st isn’t just another date on the calendar—it’s a deadline that has Pentagon planners working around the clock.

The implications are staggering. According to the Center for Strategic and International Studies (CSIS), the US defense industry is facing significant challenges caused by its limited production ability to meet rising defense technology needs. By restricting exports, China may be able to accelerate the expansion of its military strength at a faster pace than the U.S.

Meanwhile, China is rapidly scaling up its munitions manufacturing capacity and acquiring advanced weapons platforms at a rate estimated to be five to six times faster than that of the United States. While America scrambles to secure rare earth supplies, China is outbuilding the U.S. military at a pace not seen since the height of the Cold War.

Wall Street’s Wild Ride: Rare Earth Stocks Surge

The market reaction has been nothing short of dramatic. The U.S. stock market erased about $2 trillion in value after Trump threatened massive tariffs against China. But while broad markets stumbled, rare earth stocks soared as investors bet on a domestic mining renaissance.

Stock Performance October 2025:

- MP Materials (NYSE: MP) soared 50% to close at $45.23, with market cap growing to $7.4 billion

- Energy Fuels (NYSE: UUUU) surged nearly 200% since the MP deal announcement

- NioCorp Developments up almost 200%

- USA Rare Earth gained more than 70%

- Ramaco Resources climbing 140%

As investors speculate on which companies might receive government backing next, rare earth mining stocks continue to make gains amid the battle to beat China’s dominance.

America’s $400 Million Wake-Up Call

“It’s scandalous that we don’t have a rare earths strategic reserve, that we let China monopolize 90% of the refining of rare earth materials,” said Jeremy Siegel, University of Pennsylvania professor emeritus of finance. The anger in those words reflects a growing realization: America got outmaneuvered on the strategic chessboard.

There was a time in the 1970s and ’80s when the United States was the largest producer of rare earth minerals, with most coming from the Mountain Pass Mine in California. What happened? China happened—through a combination of lower labor costs, lax environmental regulations, and strategic subsidies that made it economically unviable for Western companies to compete.

The Pentagon Strikes Back with Historic Investment

In an unprecedented move, the U.S. government announced a $400 million investment into MP Materials, making the Pentagon the company’s largest shareholder. MP Materials operates the only operational rare earth mine in the U.S. at Mountain Pass, California.

Pentagon Deal Details: The Department of Defense has agreed to buy 100% of the magnets made at MP’s new facility, called 10X, for 10 years after the plant is built. The Pentagon is guaranteeing a minimum price of $110 per kilogram for neodymium-praseodymium oxide for 10 years. If the market price drops below $110, taxpayers cover the difference. If it goes higher, the Pentagon gets 30% of the upside.

This price floor mechanism is crucial for market stability. According to The Washington Post, price support from the federal government “sends a true market signal that these investments are long term.” The price of neodymium-praseodymium oxide surged 40% in the wake of the MP deal.

The Pentagon hasn’t stopped there. It has invested $540 million so far to support a critical mineral and rare earth supply chain in the U.S. and allied nations, with more deals likely in the pipeline. Companies like Energy Fuels, NioCorp Developments, and USA Rare Earth are all positioning themselves as the next beneficiaries of government support.

The Reality Check: Years Behind China

Despite the flurry of activity and investment, the hard truth is sobering. In 2024, MP Materials announced record production of 1,300 tons of neodymium-praseodymium oxide. Meanwhile, in the same year, China produced an estimated 300,000 tons of neodymium-iron-boron magnets. America isn’t just behind—it’s lapping orders of magnitude behind.

Even when MP Materials’ facilities are fully operational, the company will only be producing 1,000 tons of neodymium-boron-iron magnets by the end of 2025—less than 1 percent of the 138,000 tons China produced in 2018. And those 2018 numbers? China’s production has only grown since then.

Timeline Reality: Developing mining and processing capabilities requires a long-term effort, meaning the United States will be on the back foot for the foreseeable future. When experts celebrate that the U.S. produced its first sample of dysprosium oxide in January 2025, they’re talking about laboratory quantities—turning that into commercial-scale production could take a decade.

Energy Fuels: The Uranium Producer Turned Rare Earth Champion

Energy Fuels has emerged as a dynamic player in rare earth processing, leveraging its White Mesa Mill in Utah. In August 2025, Energy Fuels produced its first kilogram of dysprosium oxide at 99.9% purity, surpassing commercial benchmarks—a major leap toward securing a U.S. supply of ‘heavy’ rare earth oxides.

The company’s aggressive move into rare earths has been rewarded with federal contracts and explosive stock gains. Energy Fuels’ stock has surged over 420% amid trade tensions, though analysts note significant valuation concerns given the company’s current revenue of just $65 million against a market cap exceeding $6 billion.

Beyond Defense: The Broader Economic Threat

While defense applications grab headlines, the civilian economy is equally vulnerable. Rare earths power the clean energy transition—electric vehicles, wind turbines, and solar panels all depend on these materials.

The automotive industry is particularly exposed. Every electric vehicle contains permanent magnets made with rare earth elements. As automakers race to electrify their fleets, they’re discovering that their supply chains run through Beijing. Trump administration officials tacitly acknowledged America’s dependence by excluding critical minerals from reciprocal tariffs.

The semiconductor industry faces similar challenges. Advanced chips require rare earth elements for manufacturing equipment and substrate materials. Applications for rare earth exports used in producing sub-14 nanometer semiconductors, advanced memory chips, semiconductor manufacturing equipment, or artificial intelligence will face particular scrutiny under the new restrictions.

China’s Master Strategy: Economic Lawfare

This marks a significant development as the debut of a Chinese version of the “Foreign Direct Product Rule,” a signature tool Washington has used for decades to exert power and control. Beijing has essentially copied America’s own playbook—the same mechanism the U.S. used to choke off semiconductor supplies to Huawei—and turned it against Western companies.

But this isn’t just about one set of export controls. China now wields over 20 laws and regulatory statutes—spanning cybersecurity, foreign investment screening, maritime safety, and even the corporate social credit system—creating a dense framework designed to compel, retaliate, and reward in service of national objectives.

Critical Minerals = Geopolitical Power

This is what experts call “lawfare”—using legal and regulatory mechanisms as weapons of economic warfare. Chinese citizens are also prohibited from supporting overseas activities related to rare earth extraction and magnet manufacturing without approval from Beijing.

The Geopolitical Chess Match: Trump vs. Xi

The new restrictions on rare earths come amid a freeze by China on buying U.S. soybeans from the autumn harvest—another instance of Beijing building leverage with Washington. China is wielding multiple economic weapons simultaneously, each designed to pressure different constituencies within the United States.

The restrictions provide President Xi Jinping with significant leverage ahead of the expected meeting with President Trump in South Korea. When Trump and Xi sit down, rare earths will be a major bargaining chip—perhaps the major bargaining chip.

The response from Washington has been predictably aggressive. Trump announced new tariffs of 100% on imports from China “over and above any Tariff that they are currently paying” beginning Nov. 1, along with export controls on “any and all critical software.” But tariffs on finished goods are a blunt instrument when the problem is supply chain dependencies built over decades.

China accused the U.S. of “double standards” and defended its new export controls as a “legitimate” measure under international law, stating “China’s position on the trade war is consistent: we do not want it, but we are not afraid of it.” Beijing’s confidence stems from knowing it holds structural advantages that can’t be quickly overcome.

What Businesses Need to Know Now

For companies dependent on rare earth supply chains, the message is clear: diversify or die. The European Chamber of Commerce said that Beijing’s tight grip had cost at least one member “millions of euros” while other members cited inconsistent procedures for obtaining export approvals.

The new licensing requirements create operational nightmares. Companies must explain the intended use of products they wish to make using Chinese rare earth metals. There will be certain exemptions under the new rules, including exports for emergency medical situations or disaster relief, with a “transition period” allowing businesses to fulfill existing contracts and meet compliance requirements.

But that transition period is temporary, and the December 1st deadline is approaching fast. Companies are already experiencing delays. License applications are backing up, and approval timelines remain uncertain. For industries operating on just-in-time manufacturing principles, these delays could prove catastrophic.

The Path Forward: Building Domestic Supply Chains

China’s willingness to use its trade heft to advance geopolitical goals should wake policymakers in the West to the burgeoning power of China’s manufacturing supply chain and its control over certain “chokepoint” technologies. The rare earth crisis is a wake-up call, but the question is whether America will answer it with sustained commitment or just another round of short-term fixes.

Building a domestic rare earth supply chain requires more than government investment. It requires:

1. Environmental Trade-offs

Part of why China dominates rare earth processing is willingness to tolerate environmental damage. American projects face stringent regulations that China doesn’t. Policymakers must decide which environmental rules can be relaxed for strategic industries without causing unacceptable harm.

2. Workforce Development

Mining and processing rare earths requires specialized expertise. The U.S. lost this knowledge base over decades of offshoring. Training a new generation of metallurgists, chemical engineers, and mining specialists takes years.

3. Allied Coordination

For rare earths and other critical minerals, efforts should include creating a network of mining, smelting and processing companies that lie beyond China’s ownership and control. Australia, Canada, and European allies all have rare earth resources that could be developed cooperatively.

4. Patient Capital

Markets reward quarterly results; building mines and processing facilities takes decades. The Pentagon’s price floor mechanism for MP Materials is a start, but similar structures may be needed across the supply chain to encourage private investment.

5. Technology Development

America’s advantage lies in innovation. Developing more efficient extraction methods, substitution technologies, and recycling capabilities could reduce dependence on virgin rare earth mining.

Key Rare Earth Stocks to Watch in 2025

For investors looking to capitalize on America’s rare earth renaissance, these companies represent the frontline of domestic production:

Top U.S. Rare Earth Investment Opportunities:

- MP Materials (NYSE: MP) – Only operational rare earth mine in the U.S., Pentagon’s largest investment partner

- Energy Fuels (NYSE: UUUU) – White Mesa Mill producing multiple rare earth oxides, 200%+ stock gain

- USA Rare Earth – Integrated mine-to-magnet strategy, acquired Less Common Metals for $100M

- NioCorp Developments – Developing niobium and rare earth resources, 200%+ surge

- Ramaco Resources – Critical minerals development, 140% gain

- Lynas Rare Earths (OTC: LYSDY) – Building Texas processing facility with Pentagon support

According to analysts at MINING.COM, “It’s a template for industrial policy, a national security investment, and a clear signal: the West is finally serious about rare earth resilience.”

The Supply Chain Reckoning

The rare earth crisis crystallizes everything wrong with decades of globalization-at-any-cost thinking. In pursuit of cheaper consumer goods and higher corporate profits, America outsourced not just manufacturing jobs but strategic capabilities essential to national security.

“This will certainly also further accelerate U.S. efforts to develop our own rare earth resources”—but acceleration from a near-standing start still means years of vulnerability. China built its rare earth dominance methodically over decades. America can’t rebuild what was lost overnight, no matter how much money the Pentagon throws at the problem.

The Bottom Line: The magnet squeeze isn’t just about magnets. It’s about dependency, vulnerability, and the price of strategic negligence. As December 1st approaches and export restrictions tighten, American industry faces a sobering reality: the global supply chains that seemed so efficient and cost-effective were actually built on assumptions that no longer hold.

The question now isn’t whether America needs to rebuild rare earth supply chains—it’s whether the country has the political will and strategic patience to see the effort through. Because in the new era of great power competition, economic security is national security, and every rare earth element counts.

With the upcoming Trump-Xi meeting, volatile stock markets, and the December 1st deadline looming, 2025 may be remembered as the year America finally woke up to the critical minerals crisis—or the year it became too late to catch up.

Stay Informed on Critical Minerals News

The rare earth supply chain crisis is evolving rapidly. Bookmark this page and follow developments from trusted sources including CNBC Markets, Center for Strategic & International Studies, and U.S. Geological Survey for the latest updates on rare earth production, investment opportunities, and national security implications.

Disclaimer: This article is for informational purposes only and does not constitute investment advice. Investing in rare earth mining stocks involves significant risk, including the possible loss of principal. The rare earth sector is highly volatile and subject to geopolitical, regulatory, and market risks. Past performance does not guarantee future results. Always conduct your own due diligence and consult with a qualified financial advisor before making investment decisions. Stock prices and market data current as of October 20, 2025.

#RareEarth #CriticalMinerals #NationalSecurity #SupplyChain #Defense #China #US #Investing #Geopolitics