The headline seemed routine at first: another FDA product recall, another batch of contaminated medicine pulled from shelves. But beneath the sterile language of FDA alerts and voluntary recalls lies a disturbing reality—one that reveals systemic failures in pharmaceutical manufacturing that continue to put lives at risk, particularly those of the most vulnerable: children.

The Latest Crisis: Contamination Hits American Homes

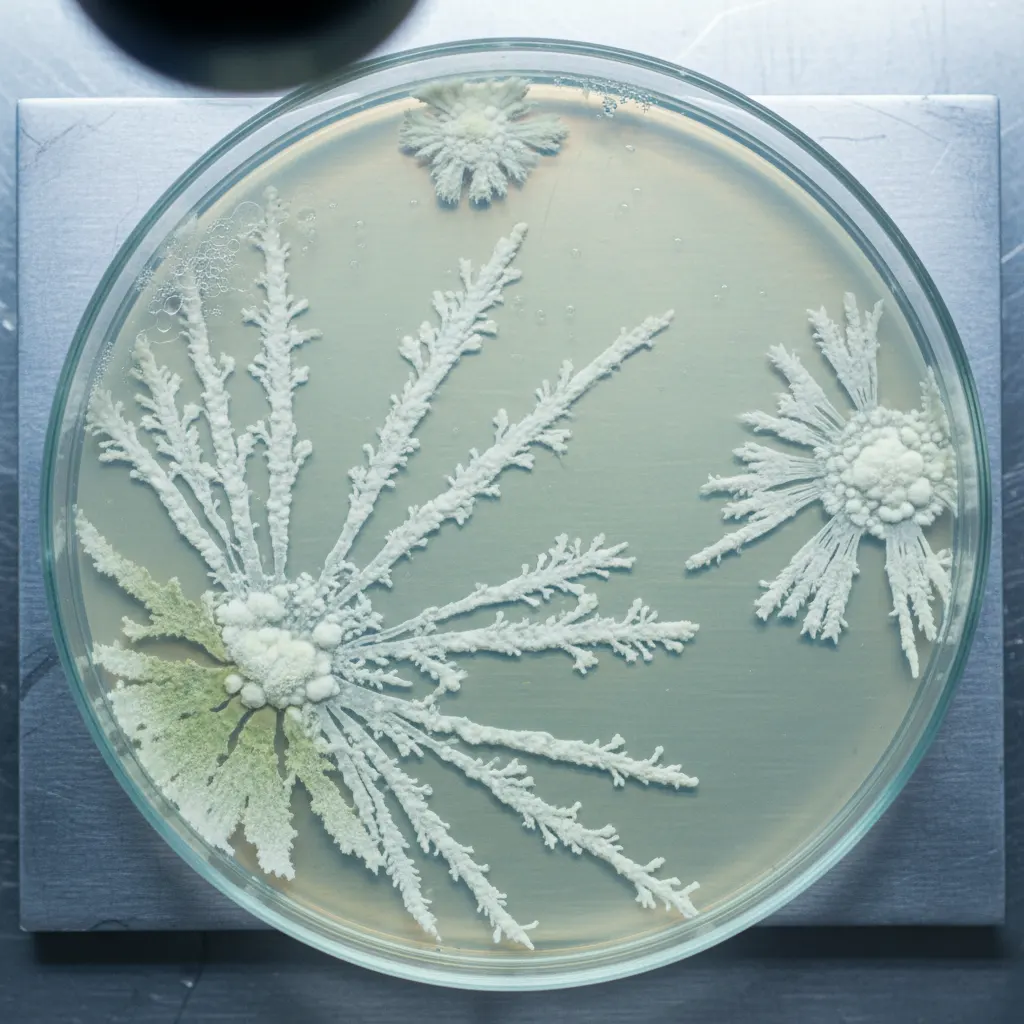

In June 2025, Medtech Products Inc. issued a nationwide recall of Little Remedies Honey Cough Syrup after discovering contamination with Bacillus cereus, a bacterium that can cause severe foodborne illness and, in high concentrations, death. According to the FDA recall notice, the recall affected over 245,000 units distributed across the United States from December 2022 through June 2025—meaning contaminated product potentially sat on pharmacy and retail shelves for more than two years.

245,352 Contaminated units distributed nationwide over 2.5 years

The contaminated syrup can trigger two distinct types of illness: acute symptoms including nausea, vomiting, and stomach cramps that begin within one to six hours of consumption, or delayed effects manifesting as severe diarrhea and stomach cramps eight to sixteen hours later. While healthy individuals might recover from short-term illness, the FDA explicitly warned that “exposure to high levels of foodborne B. cereus can cause death.”

Recalled Product Details:

- Product: Little Remedies Honey Cough Syrup (4 FL OZ)

- UPC Code: 7-56184-10737-9

- Lot Numbers: 0039, 0545, 0640, 0450, 1198

- Expiration Dates: November 2025 – December 2026

- Distribution: Nationwide through major retailers and online

For refunds, contact: (800) 754-8853 or [email protected]

This wasn’t an isolated incident. Just months earlier, in January 2024, Haleon recalled multiple lots of Robitussin Honey CF Max Day and Nighttime cough syrups due to microbial contamination that posed “severe or life-threatening events” for immunocompromised individuals, including fungemia and disseminated fungal infections.

A Global Pattern of Deadly Negligence

While American consumers have been fortunate that no deaths were reported in these recent recalls, the international picture tells a far more tragic story—one that exposes the true cost of systemic quality failures in pharmaceutical manufacturing.

India’s Recurring Nightmare

In October 2024, Indian parents watched in horror as their children developed acute kidney failure after taking contaminated cough syrup for ordinary colds. Twenty-four children died across multiple states, with cases linked to three different manufacturers: Sresan Pharmaceutical’s Coldrif, Rednex Pharmaceuticals’ Respifresh TR, and Shape Pharma’s ReLife syrup.

The culprit? Toxic industrial chemicals—diethylene glycol (DEG) and ethylene glycol (EG)—used as cheap substitutes for pharmaceutical-grade sweetening agents. These colorless, odorless, sweet-tasting chemicals are the same substances found in antifreeze, brake fluid, and engine coolant. When ingested by children, they cause respiratory failure, kidney damage, disability, and death.

Global Death Toll from Contaminated Cough Syrups (2022-2024):

- The Gambia, 2022: At least 66 children died from cough syrup manufactured in India

- Indonesia, 2022: 144 pediatric deaths linked to contaminated syrups

- Uzbekistan, 2022: 268 people died from contaminated medications

- Cameroon, 2023: At least 12 children perished from Indian-manufactured cough syrup

- India, 2024: 24 children died from DEG-contaminated cough syrup

Total: Over 300 deaths documented by WHO in two years

The World Health Organization documented over 300 deaths connected to contaminated medicines in just a two-year period from 2022-2024. According to NPR’s investigation, in five of the nine WHO warnings issued about contaminated cough syrups during this period, Indian manufacturers were identified as the source.

The Root Causes: Why Quality Systems Keep Failing

The recurring nature of these tragedies points to systemic failures that extend far beyond isolated procedural lapses. Multiple factors converge to create an environment where contaminated medicines can reach consumers:

1. Inadequate Quality Unit Oversight

FDA warning letters issued throughout 2025 reveal a disturbing pattern: Quality Units in pharmaceutical facilities—particularly in emerging markets like China, India, Malaysia, and Thailand—lack the authority, resources, and independence to enforce good manufacturing practices (GMP).

These aren’t minor administrative issues. The Quality Unit serves as the cornerstone of pharmaceutical quality systems—the final safeguard between contaminated products and consumers. When these units are undermined, compromised, or poorly resourced, the entire quality framework collapses.

2. Cost-Cutting and Corner-Cutting

The economic incentives in pharmaceutical manufacturing, particularly for low-cost over-the-counter medicines, create perverse pressures that prioritize profit over safety. Manufacturers seeking to reduce costs cut corners by:

- Substituting cheap industrial-grade chemicals for pharmaceutical-grade ingredients

- Failing to test each batch of raw materials for contamination

- Skipping proper validation of manufacturing processes

- Neglecting equipment maintenance and environmental controls

In the October 2024 Indian tragedy, investigations revealed that manufacturers were not testing each batch of ingredients, despite regulatory directives issued after previous contamination incidents. The toxic diethylene glycol that killed 24 children could have been detected with basic laboratory testing—but such testing was either not performed or its results were ignored.

3. Weak Regulatory Infrastructure

While the FDA maintains rigorous oversight of domestic manufacturers and imports into the United States, many countries lack equivalent regulatory capacity. India’s Central Drugs Standard Control Organization (CDSCO), despite recent reforms, has struggled to implement comprehensive quality standards across the country’s vast pharmaceutical sector.

The gap between regulatory standards in developed versus developing nations creates opportunities for substandard products to proliferate in markets with weaker oversight. When these products are exported—sometimes with fraudulent documentation claiming they meet higher standards—the consequences can be deadly.

4. Insufficient Testing and Validation

According to research published in PMC, between January 2017 and September 2019, 85.1% of drug recalls were due to quality issues, with lack of sterility being the most frequent problem (83.7% of quality recalls). FDA warning letters in 2025 repeatedly cited manufacturers for:

- Inadequate supplier qualification and oversight (over 30% of citations)

- Failures in process validation and equipment qualification

- Data integrity violations, including fabricated records and altered test results

- Incomplete batch records and documentation gaps

- Lack of environmental monitoring in cleanroom facilities

5. The Shelf Life Problem

The Little Remedies recall raises a particularly troubling question: How does contaminated product remain on shelves for over two years before detection? The recall notice cited not only microbial contamination but “loss of shelf stability”—suggesting the product degraded over time in ways that weren’t anticipated or monitored.

The Human Cost of Systems Failure

“Parents in Chhindwara, India, watched their children develop kidney failure from what they believed was safe medicine for a common cold. These weren’t deaths from incurable diseases—they were poisonings from products that should have provided comfort and healing.”

Behind the statistics and technical jargon are real families torn apart by preventable tragedies. Gambian families buried 66 children who died from contaminated syrup. Even in the United States, where no deaths were reported from recent recalls, thousands of families unknowingly gave their children potentially contaminated products.

Parents checking medicine cabinets in June 2025 discovered they had been administering bacteria-laden syrup to their sick children for months or even years.

Regulatory Response: Too Little, Too Late?

The pharmaceutical industry and regulators have taken steps to address quality concerns, but critics argue these measures remain insufficient:

Recent Initiatives

FDA Quality Management Maturity (QMM) Program: Launched to incentivize manufacturers to exceed minimum CGMP requirements and develop mature quality management systems. The program recognizes that simply meeting baseline regulations isn’t enough—manufacturers must embrace cultures of continuous improvement and proactive quality management.

Enhanced Import Screening: The FDA has intensified scrutiny of foreign manufacturers, with warning letters to international facilities increasing from 22.9% in 2019 to 33% in recent years.

India’s Regulatory Reforms: Following the 2022 global tragedies, India established the Online National Drug Licensing System and implemented additional screening requirements for exported cough syrups. However, implementation has been inconsistent.

WHO Global Surveillance: The World Health Organization has issued nine warnings about contaminated cough syrups since 2022 and published a joint report with the United Nations documenting the scale of the problem.

The Gaps That Remain

- Reactive vs. Proactive: Regulatory action often follows tragedy rather than preventing it

- Limited Resources: Regulatory agencies cannot inspect every facility or test every batch

- Global Supply Chain Complexity: Modern pharmaceutical supply chains span multiple countries and dozens of suppliers

- Economic Incentives Misalignment: Investing in quality can put manufacturers at an economic disadvantage

The Path Forward: Systemic Solutions for Systemic Problems

Preventing future tragedies requires comprehensive reforms that address root causes rather than symptoms:

1. Strengthen Quality Unit Independence and Authority

Pharmaceutical companies must ensure Quality Units have direct reporting lines to executive leadership, independent of production management, with authority to halt production and reject batches without override.

2. Implement Mandatory Batch Testing

All manufacturers should be required to test every batch of raw materials and finished products for identity, purity, toxic contaminants (especially DEG and EG), microbial contamination, and stability throughout shelf life.

3. Enhance Supply Chain Transparency

Global pharmaceutical supply chains need complete traceability from raw material source to consumer, with blockchain or similar technology to prevent fraudulent documentation.

4. Increase Regulatory Resources and Coordination

Governments must fund adequate staffing and technology for drug regulators, enhance international cooperation and information sharing, and impose meaningful penalties that reflect the true cost of harm.

5. Realign Economic Incentives

The market must reward quality through preferential procurement for manufacturers with mature quality systems and insurance frameworks that internalize the cost of quality failures.

6. Embrace Technology and Innovation

Modern quality tools offer unprecedented capabilities including real-time process monitoring, predictive analytics, continuous manufacturing with in-line testing, and digital quality management systems with complete audit trails.

The Unacceptable Status Quo

The cough syrup tragedies—from India’s pediatric deaths to America’s widespread recalls—expose an uncomfortable truth: our pharmaceutical quality systems are failing. These aren’t isolated incidents or unavoidable accidents. They are predictable consequences of known systemic weaknesses that we have collectively failed to address.

Every parent should be able to trust that the medicine they give their sick child is safe. Every patient should expect that the drugs they take will help rather than harm. These are not unreasonable expectations—they are fundamental requirements of a functioning healthcare system.

“The technical solutions exist. The regulatory frameworks have been developed. What’s lacking is the collective will to prioritize safety over cost, to demand excellence rather than accept adequacy, and to hold ourselves accountable when systems fail.”

Until manufacturers, regulators, and policymakers treat pharmaceutical quality as the life-and-death issue it truly is, more children will die from contaminated medicines. More families will discover they unwittingly gave their loved ones poisoned products. More recalls will make headlines, followed by inadequate reforms, followed by more tragedies.

We know better. We can do better. The question is: will we?

Take Action to Protect Your Family

#FDARecall #DrugSafety #PharmaceuticalNews #MedicationSafety #ChildSafety #PublicHealth #HealthAlert #DrugRecall2025 #FDAAlert #PatientSafety