A powerful alliance is quietly transforming global manufacturing. The combined strengths of Nvidia, Google, and Hyundai are redefining what modern factories look like—faster, smarter, and increasingly autonomous.

The partnership combines AI computing, cloud intelligence, and industrial production. Together, they’re accelerating the move to fully digital, software-defined manufacturing.

Why This Alliance Matters

Manufacturing is undergoing its biggest transformation since the industrial revolution. Factories are rapidly adopting automation and AI. This shift is driven by rising labor costs, supply chain disruptions, and growing demand for mass customization.

This is where the Nvidia–Google–Hyundai partnership becomes especially significant—each company controls a critical layer of the modern factory stack.

Nvidia: The AI Engine Powering Automation

Nvidia has emerged as the backbone of industrial AI. Its GPUs and platforms like Nvidia Omniverse enable manufacturers to simulate entire factory floors in real time, test workflows, and train robots before physical deployment.

By powering machine vision, robotics, and digital twins, Nvidia technology allows factories to predict failures, optimize layouts, and reduce downtime—key advantages in competitive global markets.

Google: Cloud Intelligence at Industrial Scale

Google brings the data layer. Through Google Cloud, manufacturers gain access to scalable AI models, real-time analytics, and secure infrastructure capable of handling massive sensor and production data streams.

Tools such as predictive maintenance, demand forecasting, and AI-driven quality inspection are increasingly powered by Google’s cloud-based machine learning systems.

Hyundai: Turning AI Into Physical Reality

As one of the world’s largest industrial and automotive manufacturers, Hyundai plays a crucial role by deploying these technologies at scale. From automotive plants to robotics subsidiaries, Hyundai is actively integrating AI-driven automation into real-world production environments.

Its investments in smart factories and robotics—often highlighted in industry coverage by Bloomberg—serve as live testbeds for next-generation manufacturing.

What the Factory Floor of the Future Looks Like

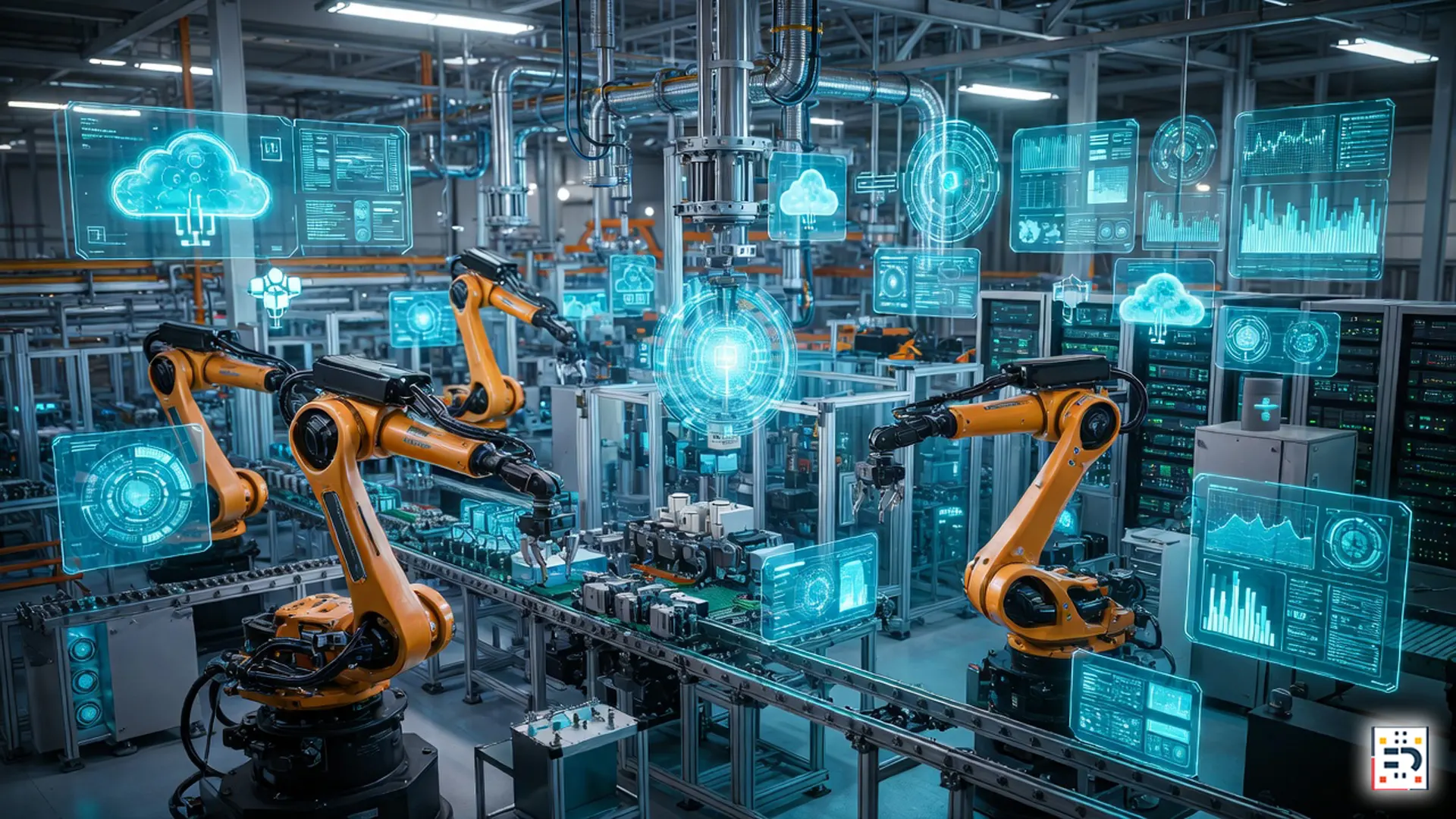

Together, Nvidia, Google, and Hyundai are shaping factories that operate more like intelligent systems than traditional assembly lines.

- AI-powered robots collaborating with human workers

- Real-time digital twins mirroring physical production

- Predictive maintenance reducing costly shutdowns

- Cloud-connected factories adapting instantly to demand

According to analysts cited by McKinsey, smart manufacturing could add trillions to global productivity over the next decade.

Implications for Jobs and Global Competition

While efficiency gains are undeniable, the alliance also raises concerns around workforce displacement. Routine factory roles are increasingly automated, while demand rises for workers skilled in AI oversight, robotics maintenance, and data analysis.

At a national level, countries that adopt smart manufacturing fastest may gain a decisive competitive edge in global trade and industrial leadership.

The Nvidia–Google–Hyundai alliance represents more than a corporate partnership—it signals a new era for industrial production. By combining AI compute, cloud intelligence, and manufacturing scale, the trio is building factories designed for speed, resilience, and constant optimization.

As this model spreads, the factory floor may soon become one of the most advanced AI environments in the global economy.

#SmartManufacturing #AIFactories #Nvidia #GoogleCloud #Hyundai #IndustrialAI #DigitalTwins #FactoryOfTheFuture #Automation #TechIndustry #digitalnewsforall